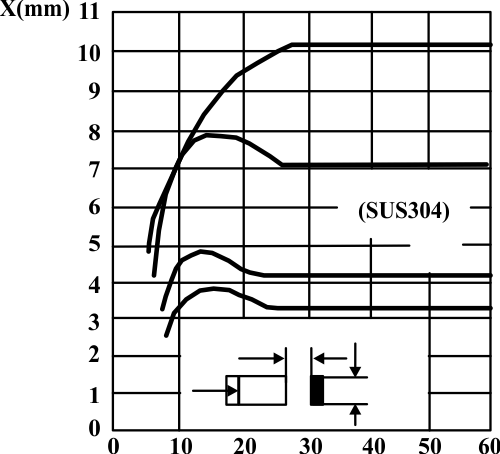

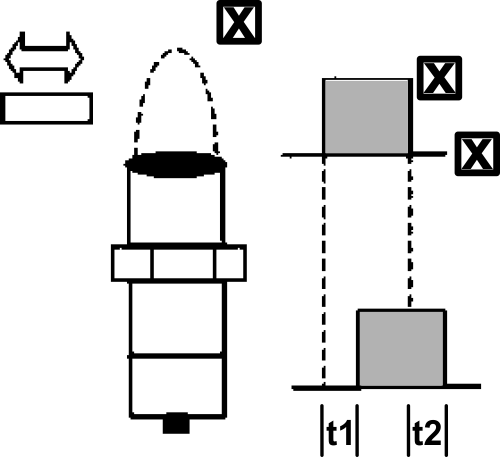

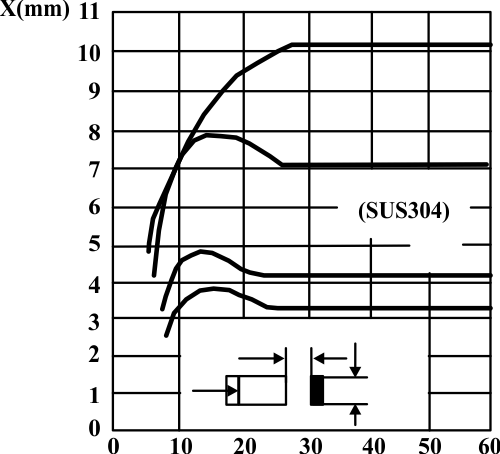

The

size of

detection object and

detection distance

|

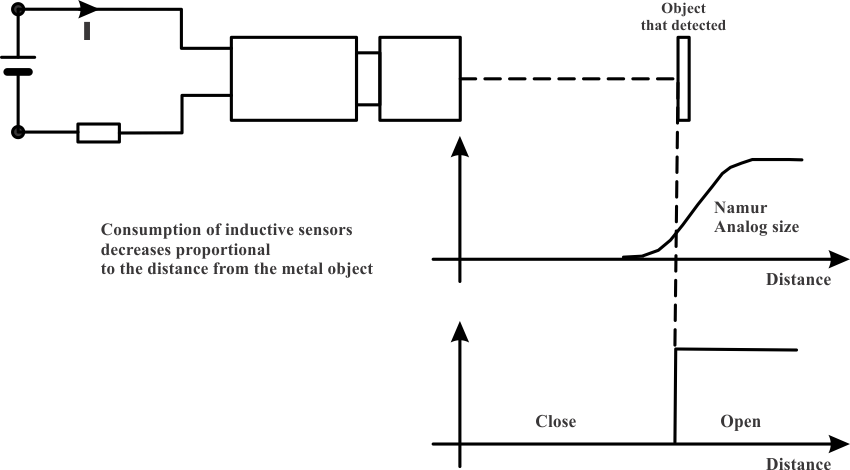

If

the

detection object is

square metal sheet

with constant

thickness

(t=1mm), detect at

detection distance X

when change its side

length d

mm.

|

When

the detected

object is bigger than

standard detected

object, on the main, the

detection distance is

constant.

According to different

machine type, sometimes

the features will be

different with that

mentioned on the left.

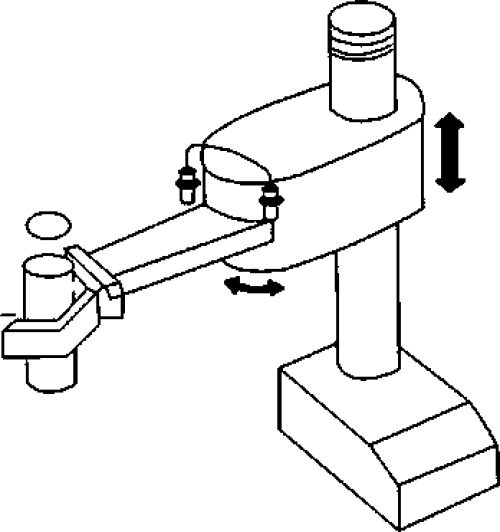

To through type, the

detection object is like

cylinder metal bar.

|

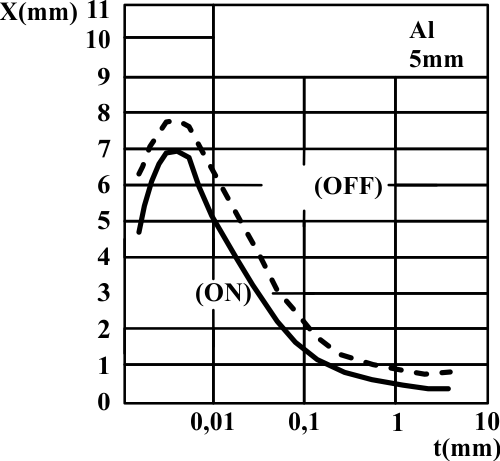

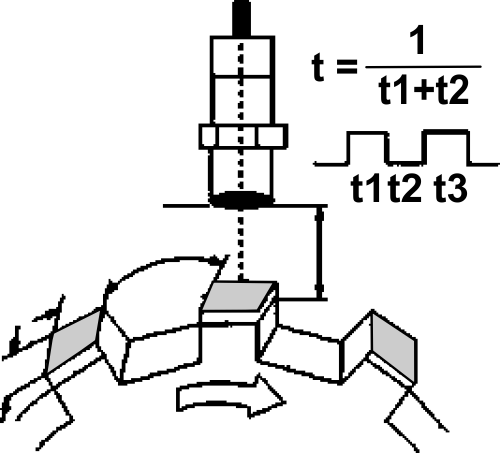

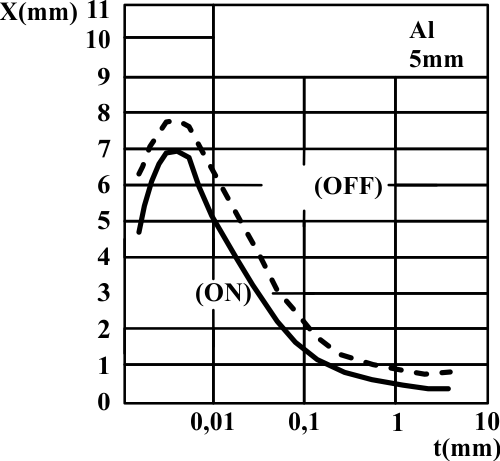

The

thickness of

detected object and

detection distance

|

Detect

at

detection distance X

mm (front detector)

when change the

thickness

of the assigned

standard detected

object 1 mm.

|

For

more than 1

mm thick magnetic

metal like iron, on

the main, the

detection distance

will not change.

|

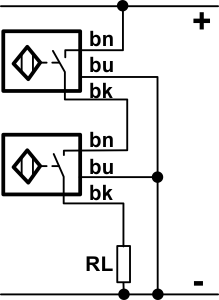

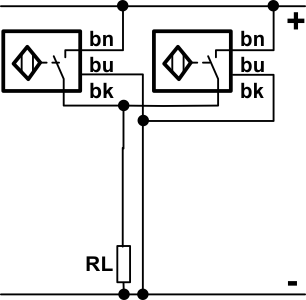

| The

effects

resulted from the

thickness of detected

object and cladding

material |

Because

the

detection to standard

detected object will

be effected by its

shape, size, material,

and various cladding

material, confirm

through

detection distance X

mm measurement.

|

The effects

resulted from detection

distance and cladding

material of the metal

excluded iron will be

different according to

different machine type.

On

the main, the machine

type which

detects all the metals

will not ne effected by

cladding material.

|